Household and power wires can be handled by one unit Wet nugget plant WN series of Sanritsu Machinery

-

Small nugget plant

WN-800 type

-

medium nugget plant

WN-2400 type

-

medium to large nugget plant

WN-3600 type

Applicable cable

Small nugget plant・ medium nugget plant・ medium to large nugget plant

-

VA wire

-

twist wire

-

three phase wires

-

high voltage wire

-

home appliance wire

-

automobile harness

-

communication wire

Series features

-

Streamlining input work One operation is possible without any hassle

- Pretreatment sorting is eliminated because it is strong against foreign substances such as plugs and connectors.

- Loading work is easy, medium-sized or larger can be loaded with power shovel. (Because it is a crusher with a pusher, bundled wire can be loaded.)

- Stable automatic operation by complete control (Stable operation by detecting the load current of the crusher and automating the input limit)

-

Wet-type specific gravity sorting (patented technology) that can sort three types. Realizes high-quality copper recovery for both household electric wires and power wires.

- High quality because intermediate specific gravity can remove (Miss cut (copper and unpeeled coating) or aluminum can be removed)

- Efficient copper recovery even with fine wires (recovery loss is extremely low due to fine tuning water shower adjustment)

- Can also handle metal mixtures other than electric wires (coupling of three sorts of copper / aluminum / plastic with replaceable sorting deck structure)

-

Advanced engineering that can handle automotive harnesses

- Easy handling of difficult-to-treat car harnesses (talc injection & advanced dust collection technology)

- Brass terminals can be removed from copper nuggets by vibrating screen

-

Abundant knowledge and know-how of specialized manufacturers of electric wire recycling machines

- High quality even with visual importance of red nuggets (stable copper drying with centrifugal dehydrator and electric heater drying process)

- Low dust scattering due to wet sorting

- Since the water used is of a circulation type, drainage is very small and can be drained by simple filtration (discharge volume less than 1m³ / month)

- No license required for intermediate treatment equipment due to valuables processing plant

-

Reliable technology and after-sales service

- Short-term installation for early full-scale operation (Thorough quality control and verification tests before shipment from the factory)

- One-stop service for stable operation after introduction (instant delivery system for consumables, data management of adjustment points)

Sorting principle of wet specific gravity sorter

The basic principle of specific gravity sorting is that it uses the same vibration and water flow as "Dustpan". Boasting stable sorting quality through patented three sorts. On the inclined deck, the plastic coating (light specific gravity) is flowed downstream by the water flow, and the copper (heavy specific gravity) is separated by specific gravity by climbing upstream due to friction with the deck bottom. Intermediate specific gravity is temporarily deposited by a weir downstream of the deck, and is discharged and removed from the bypass outside the weak water flow, enabling three types of sorting.

Difference between wet sorting and dry sorting in nugget plant

Both methods use vibration and buoyancy to select based on the specific gravity difference between copper and plastic, but each has its own characteristics.

| Wet type | Dry type | |

| Sorting method | Shower with circulating water | Air blow by blower |

| Target wire | Versatile all-purpose Suitable for thick wires to ultra-fine wires | Limited, Thick wire with large copper loss at the center of thick wire |

| Copper recovery rate | 98%~99% | 95%~98% |

| Processing power | Low ~ 1t / H | High 1t / H or more possible |

| Adjustment difficulty | Simple | Difficult |

| Ancillary equipment | Dehydration drying equipment | Exhaust dust collection equipment |

| Environmental load | Very small amount of circulating water drainage * 1m / month | Intermittent dust scattering |

※Our investigation

Presence around the world

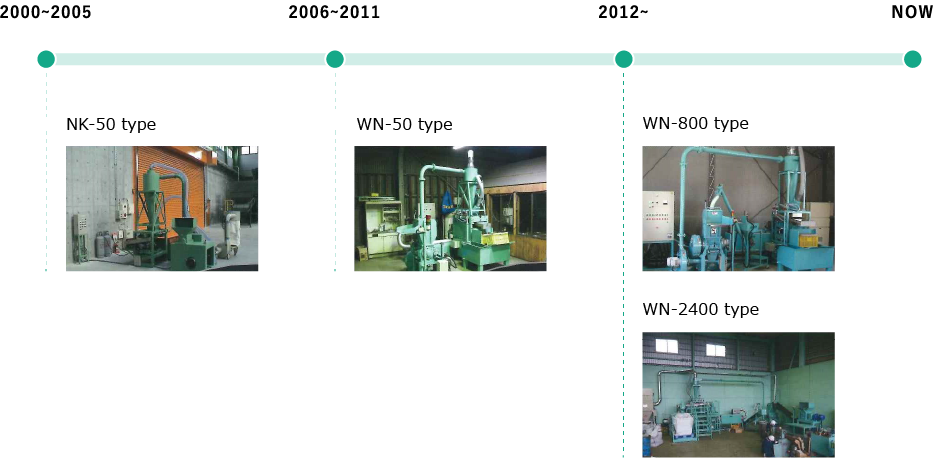

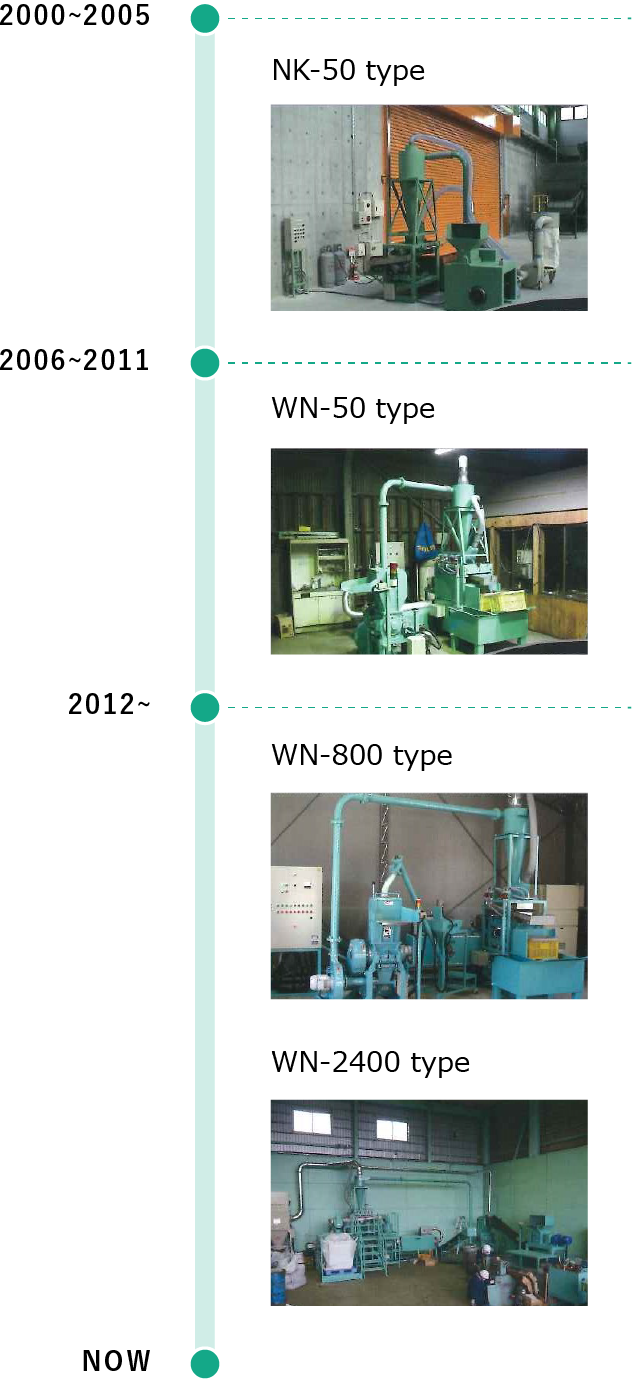

History of wet nugget plant model